We are here to help!

Leveraging Agile Practices in Chip Design for Enhanced Compliance and Reliability.

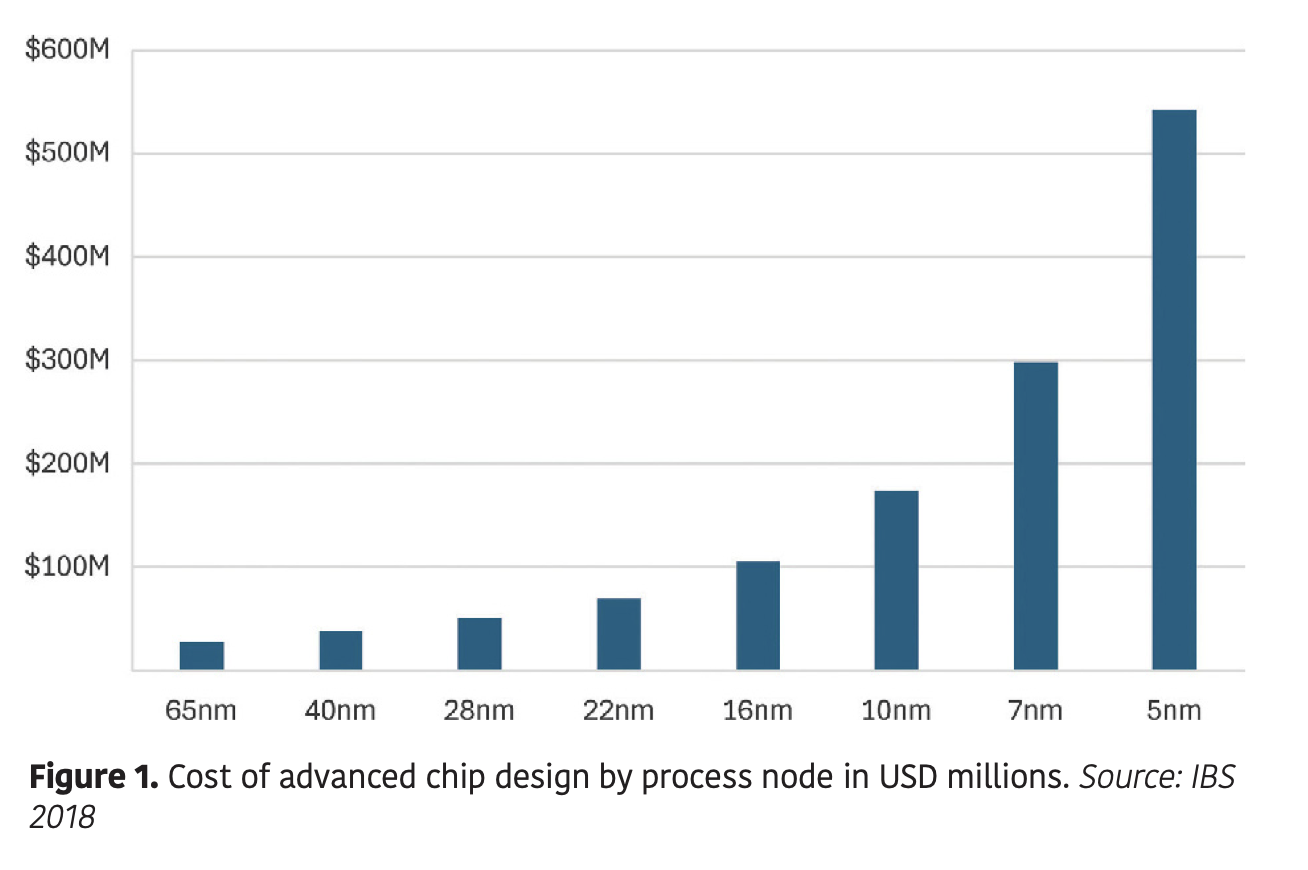

In the rapidly growing semiconductor industry, the demand for sophisticated, reliable, and compliant chip designs has never been higher. Traditional chip design methodologies often relegate verification and reliability assessments to the final stages of the development cycle, leading to time-consuming revisions and increased risk of costly errors. In fact, up to 50% of the product development cycle can be consumed by verification and validation processes. As illustrated in FIGURE 1, the escalating chip design costs associated with smaller process nodes make the potential savings from streamlining validation and verification processes exceedingly significant.

As integrated circuits become increasingly more complex, ensuring their reliability and compliance with strict standards is paramount, especially for applications in automotive, healthcare, and mission-critical systems. Agile way of working —a flexible and iterative approach— offers a transformative way to integrate compliance and reliability throughout the entire chip design process. By adopting Agile practices, semiconductor design teams can reduce time-to-market, and deliver high-quality, dependable products that meet the demanding requirements of today’s market. From next week onwards every Thursday a new blog will be posted containing one of the four ideas to improve compliance and reliability.

Agile for Hardware Trainings

- 🇦🇼Aruba

- 🇦🇫Afghanistan

- 🇦🇴Angola

- 🇦🇮Anguilla

- 🇦🇽Åland Islands

- 🇦🇱Albania

- 🇦🇩Andorra

- 🇦🇪United Arab Emirates

- 🇦🇷Argentina

- 🇦🇲Armenia

- 🇦🇸American Samoa

- 🇦🇶Antarctica

- 🇹🇫French Southern Territories

- 🇦🇬Antigua and Barbuda

- 🇦🇺Australia

- 🇦🇹Austria

- 🇦🇿Azerbaijan

- 🇧🇮Burundi

- 🇧🇪Belgium

- 🇧🇯Benin

- 🇧🇶Bonaire, Sint Eustatius and Saba

- 🇧🇫Burkina Faso

- 🇧🇩Bangladesh

- 🇧🇬Bulgaria

- 🇧🇭Bahrain

- 🇧🇸Bahamas

- 🇧🇦Bosnia and Herzegovina

- 🇧🇱Saint Barthélemy

- 🇧🇾Belarus

- 🇧🇿Belize

- 🇧🇲Bermuda

- 🇧🇴Bolivia, Plurinational State of

- 🇧🇷Brazil

- 🇧🇧Barbados

- 🇧🇳Brunei Darussalam

- 🇧🇹Bhutan

- 🇧🇻Bouvet Island

- 🇧🇼Botswana

- 🇨🇫Central African Republic

- 🇨🇦Canada

- 🇨🇨Cocos (Keeling) Islands

- 🇨🇭Switzerland

- 🇨🇱Chile

- 🇨🇳China

- 🇨🇮Côte d'Ivoire

- 🇨🇲Cameroon

- 🇨🇩Congo, The Democratic Republic of the

- 🇨🇬Congo

- 🇨🇰Cook Islands

- 🇨🇴Colombia

- 🇰🇲Comoros

- 🇨🇻Cabo Verde

- 🇨🇷Costa Rica

- 🇨🇺Cuba

- 🇨🇼Curaçao

- 🇨🇽Christmas Island

- 🇰🇾Cayman Islands

- 🇨🇾Cyprus

- 🇨🇿Czechia

- 🇩🇪Germany

- 🇩🇯Djibouti

- 🇩🇲Dominica

- 🇩🇰Denmark

- 🇩🇴Dominican Republic

- 🇩🇿Algeria

- 🇪🇨Ecuador

- 🇪🇬Egypt

- 🇪🇷Eritrea

- 🇪🇭Western Sahara

- 🇪🇸Spain

- 🇪🇪Estonia

- 🇪🇹Ethiopia

- 🇫🇮Finland

- 🇫🇯Fiji

- 🇫🇰Falkland Islands (Malvinas)

- 🇫🇷France

- 🇫🇴Faroe Islands

- 🇫🇲Micronesia, Federated States of

- 🇬🇦Gabon

- 🇬🇧United Kingdom

- 🇬🇪Georgia

- 🇬🇬Guernsey

- 🇬🇭Ghana

- 🇬🇮Gibraltar

- 🇬🇳Guinea

- 🇬🇵Guadeloupe

- 🇬🇲Gambia

- 🇬🇼Guinea-Bissau

- 🇬🇶Equatorial Guinea

- 🇬🇷Greece

- 🇬🇩Grenada

- 🇬🇱Greenland

- 🇬🇹Guatemala

- 🇬🇫French Guiana

- 🇬🇺Guam

- 🇬🇾Guyana

- 🇭🇰Hong Kong

- 🇭🇲Heard Island and McDonald Islands

- 🇭🇳Honduras

- 🇭🇷Croatia

- 🇭🇹Haiti

- 🇭🇺Hungary

- 🇮🇩Indonesia

- 🇮🇲Isle of Man

- 🇮🇳India

- 🇮🇴British Indian Ocean Territory

- 🇮🇪Ireland

- 🇮🇷Iran, Islamic Republic of

- 🇮🇶Iraq

- 🇮🇸Iceland

- 🇮🇱Israel

- 🇮🇹Italy

- 🇯🇲Jamaica

- 🇯🇪Jersey

- 🇯🇴Jordan

- 🇯🇵Japan

- 🇰🇿Kazakhstan

- 🇰🇪Kenya

- 🇰🇬Kyrgyzstan

- 🇰🇭Cambodia

- 🇰🇮Kiribati

- 🇰🇳Saint Kitts and Nevis

- 🇰🇷Korea, Republic of

- 🇰🇼Kuwait

- 🇱🇦Lao People's Democratic Republic

- 🇱🇧Lebanon

- 🇱🇷Liberia

- 🇱🇾Libya

- 🇱🇨Saint Lucia

- 🇱🇮Liechtenstein

- 🇱🇰Sri Lanka

- 🇱🇸Lesotho

- 🇱🇹Lithuania

- 🇱🇺Luxembourg

- 🇱🇻Latvia

- 🇲🇴Macao

- 🇲🇫Saint Martin (French part)

- 🇲🇦Morocco

- 🇲🇨Monaco

- 🇲🇩Moldova, Republic of

- 🇲🇬Madagascar

- 🇲🇻Maldives

- 🇲🇽Mexico

- 🇲🇭Marshall Islands

- 🇲🇰North Macedonia

- 🇲🇱Mali

- 🇲🇹Malta

- 🇲🇲Myanmar

- 🇲🇪Montenegro

- 🇲🇳Mongolia

- 🇲🇵Northern Mariana Islands

- 🇲🇿Mozambique

- 🇲🇷Mauritania

- 🇲🇸Montserrat

- 🇲🇶Martinique

- 🇲🇺Mauritius

- 🇲🇼Malawi

- 🇲🇾Malaysia

- 🇾🇹Mayotte

- 🇳🇦Namibia

- 🇳🇨New Caledonia

- 🇳🇪Niger

- 🇳🇫Norfolk Island

- 🇳🇬Nigeria

- 🇳🇮Nicaragua

- 🇳🇺Niue

- 🇳🇱Netherlands

- 🇳🇴Norway

- 🇳🇵Nepal

- 🇳🇷Nauru

- 🇳🇿New Zealand

- 🇴🇲Oman

- 🇵🇰Pakistan

- 🇵🇦Panama

- 🇵🇳Pitcairn

- 🇵🇪Peru

- 🇵🇭Philippines

- 🇵🇼Palau

- 🇵🇬Papua New Guinea

- 🇵🇱Poland

- 🇵🇷Puerto Rico

- 🇰🇵Korea, Democratic People's Republic of

- 🇵🇹Portugal

- 🇵🇾Paraguay

- 🇵🇸Palestine, State of

- 🇵🇫French Polynesia

- 🇶🇦Qatar

- 🇷🇪Réunion

- 🇷🇴Romania

- 🇷🇺Russian Federation

- 🇷🇼Rwanda

- 🇸🇦Saudi Arabia

- 🇸🇩Sudan

- 🇸🇳Senegal

- 🇸🇬Singapore

- 🇬🇸South Georgia and the South Sandwich Islands

- 🇸🇭Saint Helena, Ascension and Tristan da Cunha

- 🇸🇯Svalbard and Jan Mayen

- 🇸🇧Solomon Islands

- 🇸🇱Sierra Leone

- 🇸🇻El Salvador

- 🇸🇲San Marino

- 🇸🇴Somalia

- 🇵🇲Saint Pierre and Miquelon

- 🇷🇸Serbia

- 🇸🇸South Sudan

- 🇸🇹Sao Tome and Principe

- 🇸🇷Suriname

- 🇸🇰Slovakia

- 🇸🇮Slovenia

- 🇸🇪Sweden

- 🇸🇿Eswatini

- 🇸🇽Sint Maarten (Dutch part)

- 🇸🇨Seychelles

- 🇸🇾Syrian Arab Republic

- 🇹🇨Turks and Caicos Islands

- 🇹🇩Chad

- 🇹🇬Togo

- 🇹🇭Thailand

- 🇹🇯Tajikistan

- 🇹🇰Tokelau

- 🇹🇲Turkmenistan

- 🇹🇱Timor-Leste

- 🇹🇴Tonga

- 🇹🇹Trinidad and Tobago

- 🇹🇳Tunisia

- 🇹🇷Türkiye

- 🇹🇻Tuvalu

- 🇹🇼Taiwan, Province of China

- 🇹🇿Tanzania, United Republic of

- 🇺🇬Uganda

- 🇺🇦Ukraine

- 🇺🇲United States Minor Outlying Islands

- 🇺🇾Uruguay

- 🇺🇸United States

- 🇺🇿Uzbekistan

- 🇻🇦Holy See (Vatican City State)

- 🇻🇨Saint Vincent and the Grenadines

- 🇻🇪Venezuela, Bolivarian Republic of

- 🇻🇬Virgin Islands, British

- 🇻🇮Virgin Islands, U.S.

- 🇻🇳Viet Nam

- 🇻🇺Vanuatu

- 🇼🇫Wallis and Futuna

- 🇼🇸Samoa

- 🇾🇪Yemen

- 🇿🇦South Africa

- 🇿🇲Zambia

- 🇿🇼Zimbabwe

- No elements found. Consider changing the search query.

- List is empty.

- English

- Dutch

- German

- French

- Italian

- Spanish

- No elements found. Consider changing the search query.

- List is empty.

- Virtual

- Classroom

- No elements found. Consider changing the search query.

- List is empty.

Cookies

We use cookies to improve your experience while browsing our website. Cookies are used for ads personalisation. For more information see our Privacy Policy.